Rapidaj Detaloj

Rapidaj Detaloj

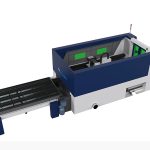

Apliko: Laser-Tranĉado

Kondiĉo: Nova

Lasero-Tipo: Fibra Lasero

Aplika Materialo: Metalo

Tranĉa Dikeco: 0-30mm

Tranĉa Areo: 1500 * 3000mm

Tranĉrapideco: 35m / min

CNC aŭ Ne: Jes

Malvarmiga Modo: Malvarmiga Akvo

Programaro pri Kontrolo: Bodor Pro

Grafika Formato Subtenita: AI, DXF, PLT

Loko de Origino: Shandong, Ĉinio (Mainland)

Marka Nomo: Bodor

Modela Nombro: P3015

Atesto: CE, ISO, SGS, FDA, BV, TUV

Post-venda Servo Provizita: Inĝenieroj haveblaj al serva maŝinaro eksterlande

Lasera potenco: 500W / 1000W / 1500W / 2000W / 3000W / 4000W

Ŝlosilvorto: Lasero-Tranĉilo

Lasera Fonto: IPG / MAX

Garantio: 3 jaroj

Grandeco: 9950 * 3050 * 2200mm

Pezo: 11000Kg

Laboranta areo: 1500 * 3000mm

Vivdaŭro: Pli ol 20 Jaroj

Malvarmigo: Malvarmiga akvo

Daŭra labortempo: 24 horoj

Karakterizaĵoj de nia lasera tranĉmaŝino

1. plena protekta kovrilo

Medio amika kaj Sana

Plena fermita protekto plibonigas uzante sekurecon; lasera protekto vitro izolas laseran radiadon al homoj; aŭtomata kolekto sistemo de fumoj kaj polvo estas medio-amika; inteligenta monitora sistemo reduktas akcidenton, igante nin ĝui belecon kaj sanon en tranĉa procezo.

2. du aŭtomata sistemo de interŝanĝaj platformoj

tempo-ŝparado kaj penado-redukto

Rapida interŝanĝo inter du platformoj multe plibonigas laboran efikecon. Transmenda sistemo per raketoj kaj pijonoj havas pli bonan rigidecon kaj pli altan precizecon, ŝparante nutradotempon, pliigante la funkciadon.

3. Apera dezajno

Ĉirkaŭita de baka farbo arĝenta dekoracio, kunordigita kun diamanttranĉa moderigita vitro kaj alpa blanka lado-dezajno, la internacia dezajno de la maŝino estas akceptita de tutmondaj konsumantgrupoj. La laborejo estas neta, orda kaj spacŝpara.

4. gisfera lito

Integrale formita, malakcepti splisadon

Uzante flokon grafitan gisferon, kies plej malalta tirforto estas 200MPa. Alta karbonenhavo, alta kunprema forto kaj alta malmoleco. Forta ŝoko-sorbado kaj eluziĝo-rezisto. Bona rolado kaj tranĉa agado. Bonega lubrikeco, koroda rezisto kaj dimensia stabileco. Malalta termika sentemo kaj lita breĉo-sentemo reduktas la perdon de ekipaĵo dum uzado, do la maŝina precizeco povus konservi dum longa tempo, kaj neniu deformado en vivociklo.

5. Auto-fokusa lasera kapo

Liberigu viajn manojn, ĝuu aŭtomatan fokuson

(1) Aŭtomata fokuso

Aplikebla al diversaj fokusoj, kiuj estas kontrolitaj per maŝina ilo-sistemo. Fokusa punkto aŭtomate ĝustigos en tranĉa procezo por atingi la plej bonan tranĉan efikon de malsamaj dikecaj tukoj.

(2) Senpaga

La fokusa distanco estas kontrolita de operaciumo. Ni ne bezonas fari manan reguligon, kiu efike evitas erarojn aŭ erarojn kaŭzitajn de mana operacio.

(3) Rapide

Ĝi povas aŭtomate ĝustigi la plej taŭgajn fokusajn punktojn en laborprocezo, multe plibonigante tranĉan rapidon;

Kiam oni anstataŭigas malsamajn materialojn aŭ malsamajn dikajn foliojn, mana fokusa lasera kapo bezonas ĝustigi fokusan distancon permane, tre malefika; aŭtomata fokusa lasera kapo povas legi sistemajn stokadparametrojn aŭtomate, tre efika;

(4) Precizeco

Pliigante boran fokusan longon, aparte fiksante truan fokusan distancon kaj tranĉantan fokusan distancon, plibonigas tranĉan precizecon.

(5) Durable

Enkonstruitaj duoblaj akvo-malvarmigaj strukturoj povas certigi konstantan temperaturon de kolimataj kaj fokusaj komponantoj, eviti trovarmiĝon de lensoj kaj plilongigi funkcidaŭron de lensoj.

Pliigante kolimadon protektan lenson kaj fokusan protektan lenson, zorge protektu ŝlosilajn komponantojn.

6. Ekrano de mastruma sistemo

Eleganta aspekto-kurbo

La unua uzinta UI-dezajnon en la mondo, kiu lasas ekranon respondi al pretiga tablo, igante pretigon pli intuicia. Elegantaj kurboj precize konvenas maŝinan korpon. Forta akvorezista spirebla sistemo kreas la plej bonan spacon, farante operacion pli oportuna. Diamanta tranĉa procezo kaj HD-plasmo hardita vitro faras ekranon pli delikata kaj komforta uzi.

7. Cast aluminio kruco

Integra ŝtalo muldilo premo fandado, malpeza, fleksebla kaj efika

Post artefarita maljuniĝo, solva traktado kaj finado, kructrabo posedas bonan integrecon, rigidecon, surfacan kvaliton, fortikecon kaj ductilecon. La metalaj trajtoj de aluminia alojo de malpeza pezo kaj forta rigideco estas helpemaj al altrapida movado en prilaborado, kaj alta fleksebleco estas utila al altrapida tranĉado de diversaj grafikaĵoj bazitaj sur alta precizeco. Luma trabo povas doni al ekipaĵo altan operacian rapidon, plibonigante pretigan efikecon por certigi pretigan kvaliton.

| Laboranta grandeco | 1500 * 3000mm |

| Lasera Potenco | 1000/1500/2000/3000 / 4000w |

| Maŝina grandeco | 9950 * 3050 * 2200mm |

| Pezo | 11000Kg |

| Maksimuma moviĝrapideco | 100m / min |

| Maksimuma Tranĉrapideco | 35m / min |

| Min Linia Larĝeco | 0.1mm |

| Tranĉanta Profundo | 0,2-6mm |

| Malvarmiga Vojo | Akvo malvarmiganta |

| Veturado kaj Transdona Vojo | Importita Serva Motoro |

| Kontinua Labora Tempo | 24 horoj |

| Pozicia Precizeco | 0.03mm |

| Rekomponebleco | 0,02mm |

Aplikaj Materialoj:

Ĝi taŭgas por tranĉi karbonŝtalon, neoksideblan ŝtalon, aluminion, kupron kaj alojajn metalajn materialojn

Aplikaj Industrioj:

La ekipaĵo plenumas la postulojn pri prilaborado de partoj de la plej multaj industrioj, la laborprecizeco estas stabila. Nuntempe, laseraj tranĉmaŝinoj estis vaste uzataj en elektroniko, elektra, mekanika aparataro, nova energio litio, pakado, suna, LED, aŭtomobila kaj aliaj industrioj.