Priskribo de la produkto

Bona kvalito Metala Folio kaj Tubo Fibro Laser Tranĉa Maŝino Uzita en Agrikultura Ekipaĵo

Produktaĵoj

Importita altpreciza pilka ŝraŭbo / rako kaj pinion-transsendo, alta precizeca lineara gvidrelo.

Importita servomotora vetursistemo, importita helikforma skatolo.

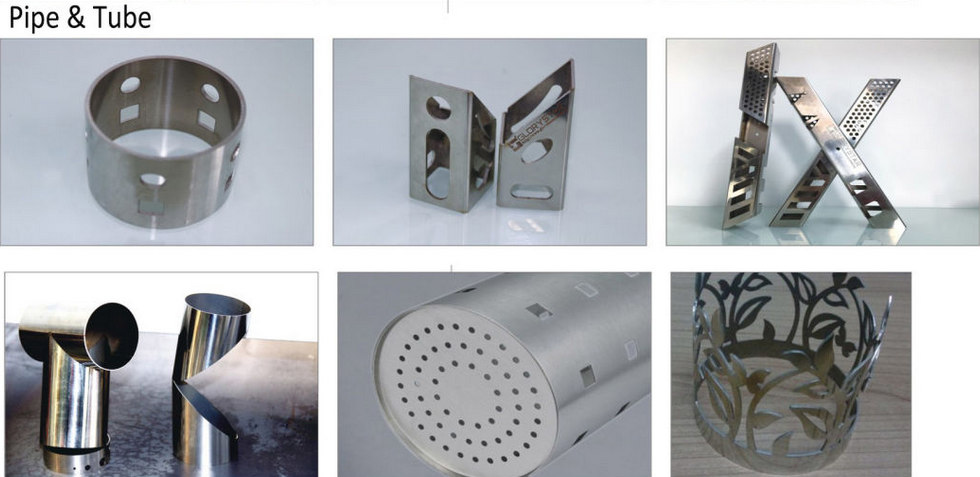

Aparta tranĉa tubo-aparato.

Rapida tranĉa rapido, alta efikeco, sekura, stabila agado.

Bonkvalita Metala Folio kaj Tuba Fibra Lasera Tranĉa Maŝino Uzata en Agrikultura Ekipaĵo

Teknikaj datumoj

| Lasera Potenco | 500W-8000W (Laŭvola) |

| Laboranta Areon | 3000 * 1500mm |

| Tuta Potenco-Konsumo | 10Kw<60Kw |

| Transdona Reĝimo | Ilaro kaj Rack Duobla stirado |

| Tensio kaj Ofteco | 380V 50Hz (60Hz) |

| Dimensio | 4800*3260*1750mm |

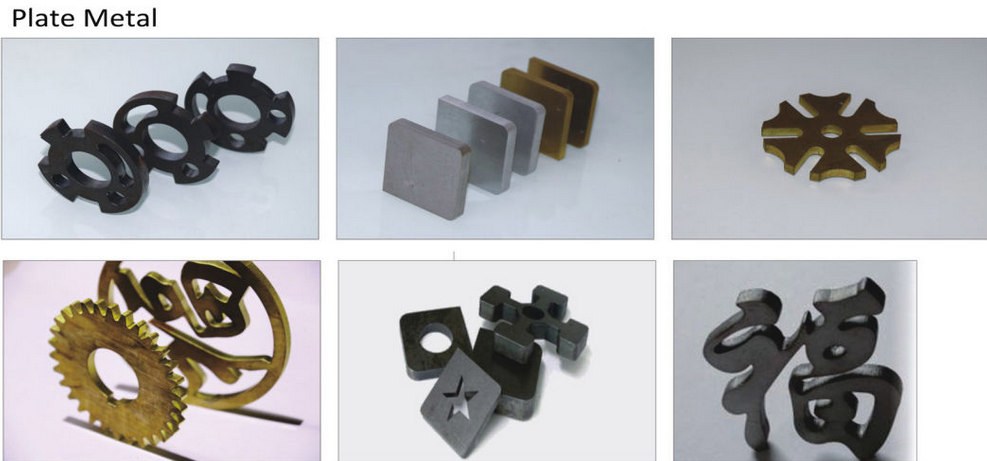

Aplikeblaj materialoj

Ĉefe aplikata al ĉiuj specoj de ladaj materialoj kun senkontakta rapida tranĉado, kavaĵo kaj truado. Kiel milda ŝtalo, neoksidebla ŝtalo, aloja ŝtalo, mangana ŝtalo, galvanizita, aluminio, kupro kaj metala tubo-prilaborado, ktp.

Aplika Industrio

Vaste uzata en ĉiuj specoj de metalproduktaj industrioj kiel lada pretigo, kuireja varo kaj banĉambro, reklamado kaj signoj, lumigado kaj aparataro, elektraj ŝrankoj, aŭtopartoj, maŝinaro kaj ekipaĵo, hejma aparato, lifto kaj precizecaj partoj, ktp.

Bazaj Informoj

Lasera Teknologio: Lasero-Kontrolo-Faŭlto-Tranĉado

Aŭtomatigo: Aŭtomata

Tipo por Tranĉa Maŝino: Laser Tranĉa Maŝino

Tipo: Metala Lasera Tranĉa Maŝino

Lasero-Tipo: Fibra Lasero

Tranĉa Akurateco: 0.01mm

Kondiĉo: Nova

Atestado: GS, Ce, ISO9001, SGS

Normo: GB

Personigita: Ne-Personigita

Materialo: Metalo

Trademark: ACCURL

Transporta Pako: Seaworthy Plywood Case

Specifo: CE SGS FDA ISO

Origino: Anhui, Ĉinio

HS-Kodo: 8456100090

Specimena Spektaklo

| 1000W fibro lasera tranĉa maŝino tranĉa parametroj | |||||||

| Materialo | Tranĉanta dikeco (mm) | Tranĉa rapideco (m/min) | Tranĉa gaso | Tranĉa premo | Ajuto | Kolimanto / Fokuso | Rimarkoj |

| Karbonŝtalo | 0.5 | 30-40 | Aero | 6 | 1.5 ununura tavolo | 75/125 | Bonvolu ĝustigi al la reala fokusa pozicio tranĉante kapon, ĉiujn parametrojn por referenco |

| 0.8 | 20-25 | Aero | 8 | 1.5 ununura tavolo | 75/125 | ||

| 1 | 18-22 | Aero | 10 | 2.0 ununura tavolo | 75/125 | ||

| 2 | 5-6.5 | Oksigeno | 3.5 | 1.2 duobla tavolo | 75/125 | ||

| 3 | 3-3.5 | Oksigeno | 0.5-1 | 1.2 duobla tavolo | 75/125 | ||

| 4 | 2-2.3 | Oksigeno | 0.5 | 1.2 duobla tavolo | 75/125 | ||

| 5 | 1.5-1.8 | Oksigeno | 0.5 | 1.2 duobla tavolo | 75/125 | ||

| 6 | 1.2-1.4 | Oksigeno | 0.5 | 1.5 duobla tavolo | 75/125 | ||

| 8 | 0.9-1.2 | Oksigeno | 0.5 | 2.0 duobla tavolo | 75/125 | ||

| 10 | 0.7-0.8 | Oksigeno | 0.5 | 2.5 duobla tavolo | 75/125 | ||

| 12 | 0.5-0.65 | Oksigeno | 0.5 | 2.5 duobla tavolo | 75/125 | ||

| Senrusta ŝtalo | 0.5 | 30-40 | Nitrogeno | 7 | 1.5 ununura tavolo | 75/125 | |

| 0.8 | 22-25 | Nitrogeno | 10 | 1.5 ununura tavolo | 75/125 | ||

| 1 | 20-23 | Nitrogeno | 12 | 1.5 ununura tavolo | 75/125 | ||

| 2 | 6-7 | Nitrogeno | 15 | 2.0 ununura tavolo | 75/125 | ||

| 3 | 2.5-2.8 | Nitrogeno | 18 | 2.0 ununura tavolo | 75/125 | ||

| 4 | 0.8-1.2 | Nitrogeno | 18 | 2.0 ununura tavolo | 75/125 | ||

| 5 | 0.6-0.8 | Nitrogeno | 18 | 2.0 ununura tavolo | 75/125 | ||

| Aluminio | 0.5 | 20-25 | Aero / Nitrogeno | 8 | 1.5 ununura tavolo | 75/125 | |

| 0.8 | 15-18 | Aero / Nitrogeno | 9 | 1.5 ununura tavolo | 75/125 | ||

| 1 | 10-12 | Aero / Nitrogeno | 12 | 1.5 ununura tavolo | 75/125 | ||

| 2 | 3-3.5 | Aero / Nitrogeno | 18 | 2.0 ununura tavolo | 75/125 | ||

| 3 | 1-1.5 | Aero / Nitrogeno | 18 | 2.0 ununura tavolo | 75/125 | ||

| Latuno | 0.5 | 22-30 | Nitrogeno | 12 | 1.5 ununura tavolo | 75/125 | |

| 0.8 | 13-17 | Nitrogeno | 12 | 1.5 ununura tavolo | 75/125 | ||

| 1 | 10-12 | Nitrogeno | 15 | 1.5 ununura tavolo | 75/125 | ||

| 2 | 2-3 | Nitrogeno | 18 | 2.0 ununura tavolo | 75/125 | ||

| 3 | 1-1.3 | Nitrogeno | 18 | 2.0 ununura tavolo | 75/125 | ||

| Kupro | 0.5 | 15-18 | Oksigeno | 12 | 1.5 ununura tavolo | 75/125 | |

| 0.8 | 8-12 | Oksigeno | 12 | 1.5 ununura tavolo | 75/125 | ||

| 1 | 5-7 | Oksigeno | 12 | 1.5 ununura tavolo | 75/125 | ||

| 2 | 0.8-1.2 | Oksigeno | 15 | 2.0 ununura tavolo | 75/125 | ||