Detala Produkta Priskribo

| Modela Numero: | ECO-FIBER-1530-6KW ACCURL | Laboranta Intervalo: | 1500x3000mm |

|---|---|---|---|

| Lasero Tipo: | Usono Raycus Fibre YLS-6Kw | Transdono: | Tajvano YYC Gear And Rack |

| Lasero-Kapo: | Svisaj Raytools Aŭtomataj | Tablo-funkciigita Sistemo: | Japana Yaskawa Serva Motoro kaj Veturanta Sistemo |

| Tuta Potenco Konsumita: | Accurl Lasero Profesia Laser-Tranĉa Programaro | Ŝlosilvortoj: | Laser Tranĉa Maŝino En Metalo |

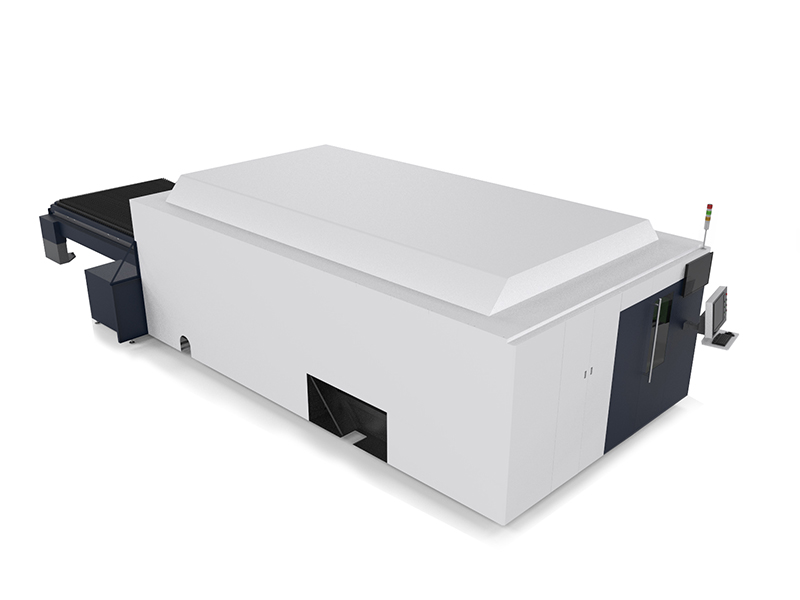

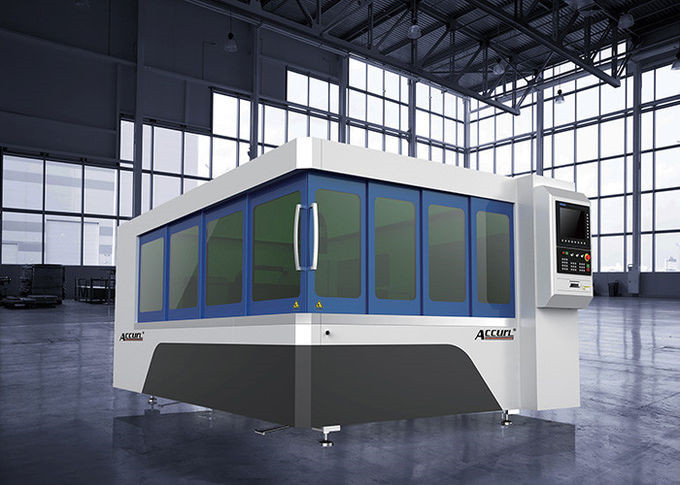

6KW Lasera Tranĉa Maŝino en 16 mm Aluminyum Alloys metalo kun Raycus Fiber Laser Power

Enkonduko de Produkto

La Fibraj Laseroj de ACCURL alportas kostefikan, malaltan prizorgadon, malaltan operacian koston kaj ekologian solvon al via organizo. Niaj fibraj laseraj maŝinoj provizas kvalitajn tranĉojn kaj toleremojn kun minimuma produktiveca perdo inter laboroj, egalante al pli alta profito de investo.

• Fabrikitaj de homoj, kiuj uzas siajn proprajn maŝinojn

• Laserradio elsendita tra optika fibro-kablo prefere ol per speguloj kaj kanaltubo rezultiganta nekonsiderindan perdon de potenco.

• La lasera lumfonto havas vivdaŭron de pli ol trioble tiu de ekvivalenta CO2-lasero.

• Pli altaj eblaj rapidoj

• Duoblaj interŝanĝeblaj tabloj permesas pli rapidan ŝarĝon kaj malŝarĝon, malpliigante malfunkciigojn

• Lasera ondolongo estas unu-dekono de CO2-lasero

• Redukto de tranĉaj variabloj aŭ tribaj scioj

• Fibra Lasero estas ekstreme efika, egalas al tre malalta konsumado

• Malalta kosto de operacio, reduktita energia kosto, ne necesas laseraj gasoj por produkti faskon

• Alta tranĉa fleksebleco (ŝtalo, neoksidebla ŝtalo, latuno, kupro, titanio, aluminio, kaj pli)

• Tre malmultaj konsumeblaj

STANDARD EKUMENTO

• Streso malpezigita lasero maŝino kadro

• Aŭtomate ŝanĝanta duobla paleta sistemo

• Lumo fonto

• Chiller

• Radan aŭ Lantek CAD/CAM-sistemo

• Preciza Rack & Pinion Drive System (Farita en Germanio)

• 3 pli malaltaj protektaj lensoj

• 5 Ajutoj ĉiu el la Sekvaj: (1.0mm, 1.2mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm)

• 3 Ceramikaj Nozzle-Adaptiloj

• Aŭtomate kalibrita cigaredingo

• Lenso kun 5.9” Fokusa Longo

• Smart Slag Collection System/ Chip Conveyor

• Fibra Radio-Transdona Sistemo (Fibra Kablo)

• Funkcias kun kaj N2 kaj O2 (tranĉaj) gasoj

• Hejma Pozicia Alliniiga Sistemo

• Helpa Gasa Elektilo

• Helpa Gasa Premo NC-funkcio

• Aŭtomata Reflektado Averto

• Laborantaj Lumoj

• Avertaj Indikaj Lampoj

• Ilaro por Purigado de lenso

• Forigo kaj Alĝustigo Iloj

• Teraj Platoj

• Uzantaj Manlibroj en la angla

OPZIONA EKIPO

• Lineara Veturado

• Polva Kolekta Unuo

• Pliaj Operaciisto-Okulvitroj

• Lenso kun 7.874” Fokusa Longo

• Sistemoj de ŝarĝo kaj malŝarĝo de folioj

• Aŭtomatigo & Stokado sistemoj

• Aŭtomata Nozzle Changer

• Propraj tablograndoj

• Ĝis 6 kW laseraj laseraj lumfontoj

• Malpeza sekureca baro

• Klimatizilo por elektra panelo

• Metalix, Almacam ktp CAD/CAM programaro

• LCM (lasero tranĉita monitoro) sentilo por trapiki detekto kaj tranĉo perdo kontrolo

Tranĉa kapo

• La lasera radio estas liverita al la tranĉa kapo per optika kablo de fibro.

• La optika fibro-kablo estas fiksita al la enigo de tranĉa kapo.

• La lasero estas liverita al la fokusa unuo post esti vicigita en la kolimilo.

• La lasera radio estas agordita al dezirata fokuso uzante la lensojn en la fokusa unuo.

• La protekta vitro protektas la lensojn de la eroj, kiuj estas kaŭzitaj de la tranĉa operacio.

• La sensila enmeto estas parto de la sistemo de kontrolo de alteco kaj helpas alĝustigi la distancon inter materialo kaj tranĉa kapo.

• Alteckontrolo estas kontrolita per la plej precizaj sensiloj en la merkato. Ĉi tio helpas produkti pli bonajn tranĉojn.

• La ĉefa funkcio de la ceramiko estas protekti la tranĉan kapon.

• La cigaredingo estas uzata por kontroli la helpajn gasojn. Ĝi ankaŭ estas parto de la kapacita kontrolsistemo.

Agordo de Lasera tranĉmaŝino

Mekanika platformo: la kovrilo, reloj, bazo, kunmetita de reflektaj kadroj kaj aliaj mekanikaj partoj;

Drivetrain: kvar ekvilibraj per la tri importitaj altprecizecaj linearaj gvidiloj, tri altprecizaj pilkŝraŭboj, zono, tri paŝomotoroj kaj pluraj ilaroj;

Helpsistemoj: Estas cirkulanta malvarmiga akvopumpilo, blovantaj kompresoroj, fumegasa ventumilo;

Optika sistemo: lasera tubo, lasera elektroprovizo, tri metalaj reflektaj speguloj kaj fokusa kapkomponento.

Avantaĝoj

1) Bonega trabo kvalito: Pli malgranda fokusa diametro kaj alta labora efikeco, alta kvalito.

2) Alta tranĉa rapido: Tranĉa rapideco estas pli ol 20m/min

3) Stabila kurado: Adoptante la plej bonajn mondajn importajn fibro-laserojn, stabila agado, ŝlosilaj partoj povas atingi 100,000 horojn;

4) Alta efikeco por fotoelektra konvertiĝo: Komparu kun CO2 lasera tranĉmaŝino, fibra optika lasero tranĉo havas trioble fotoelektran konvertan efikecon

5) Malalta kosto & Malalta bontenado: Ŝparu energion kaj protektu medion. Fotoelektra konverta indico estas ĝis 25-30%. Malalta elektra konsumo, ĝi estas nur ĉirkaŭ 20% -30% de tradicia CO2 lasera tranĉmaŝino. Fibra linio transdono ne bezonas reflekti lenson, ŝparu bontenado kosto;

6) Facilaj operacioj: transdono de fibro-linio, neniu ĝustigo de optika vojo;

7) Super flekseblaj optikaj efikoj: Kompakta dezajno, facila al fleksebla fabrikado postuloj.

Teknika Parametro

| Modelo | EKO-FIBRA 3015 / 6KW | |

| CNC-Unuo de Kontrolo | CNC-sistemo FAGOR 8060 | |

| X akso (Rack & Pinion) | 3000 mm | |

| Y akso (Rack & Pinion) | 1500 mm | |

| Akso Z (Pilka Ŝraŭbo) | 100 mm | |

| Maksimuma tranĉa kapablo | Milda stee | 32 mm |

| Senrusta ŝtalo | 16 mm | |

| Aluminio | 16 mm | |

| Dimensioj de peco de verko | 1525 x 3050 mm | |

| Rapida traverso (X kaj Y akso) | 105 m / min | |

| Akcelo | 2.5G (25m / s2) | |

| Vektora rapideco | 148 m / min | |

| Absoluta poziciigado | ± 0,08 mm | |

| Ripetebleco (X kaj Y akso) | ± 0,03 mm | |

| Maksimume ŝarĝa kapablo | 2450 kg | |

| Alta Sistemo CNC-Sistemo | FAGOR 8060 de Hispana Marko | |

| Lasera potenco | IPG YLS-6 kW el Germanio | |

| Altfara Serva motoro / veturado | FAGOR el Hispana Marko | |

| Lasero-Tranĉa Kapo | PRECITEC el Germanio | |

| Motoromotoro | STOBER el Germanio | |