Produkta Apliko

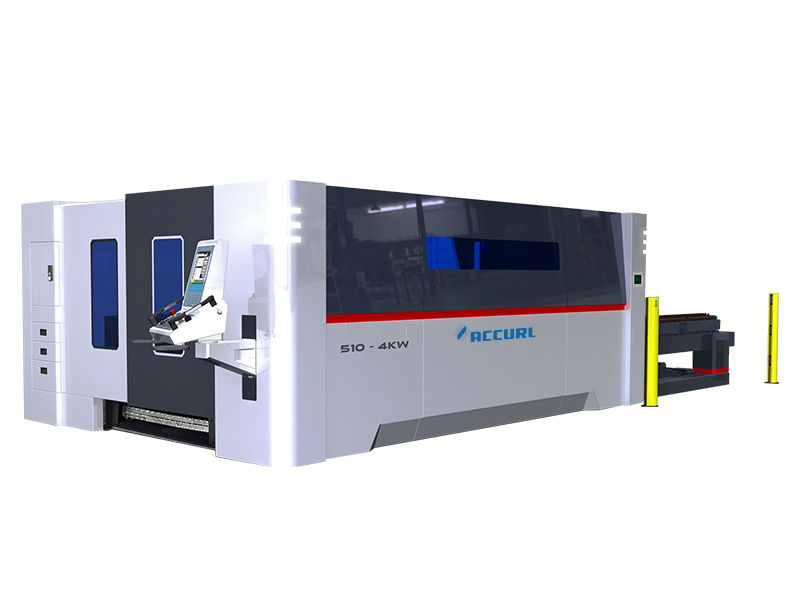

Kun la 1500mm x3000mm laborareo, la F3015 estas la baza kaj la plej ekonomia modelo por ACCURL3015. Vaste uzata en la prilaborado de reklamtabulo, metalplata strukturo, produktado de elektra arkeo Hv/lv, partoj de tekstilaj maŝinoj, kuirejaj iloj, aŭtoj, maŝinaro, lifto, elektraj partoj, tranĉaĵo de printempa bobeno, rezervaj partoj de metroo, ktp.

SPECIFICADO POR ACCURL3015 FIBRA LASER METALA TRANĈA MAŜINO | |||

Lasero-kapo | BodorGenius Auto Focus Laser Head | ||

Lasera Fonto | IPG/Maxphotonics | ||

Laboranta Areon | 1500 * 3000mm | ||

Lasera Potenco | 500w/700w/800w/1000w/1500w/2000w/2500w/3000w/4000w | ||

Malvarmiga Vojo | Akvotrinkado | ||

Kontrola Sistemo | BodorPro | ||

Maksimuma Tranĉa Rapido | 35m / min | ||

Precizeco | Pozicia Precizeco: 0.03mm. Repozicio Precizeco: 0.02mm | ||

Vetersistemo | Japanio YASKAWA Servomotoro | ||

Transdono | Tajvana arĝenta HIWIN-kvadrata relo, Tajvana YYC-ilarrako | ||

Lagro | Japana NSK-Lagro | ||

Elektraj komponantoj | Francaj Schneider elektraj komponantoj | ||

Pneŭmatikaj komponantoj | Japanaj SMC-pneŭmatikaj komponentoj | ||

Maŝino grandeco + pezo | 4550*2300*2000mm, Post pako, pezo 3000kg | ||

Maksimuma akcelo | 1.5G | ||

Aliaj partoj | Aŭtomata lubrikado-sistemo + prema mezurilo + laseraj protektaj okulvitroj + WIFI-Kontrolo + kontrolpanelo kaj ktp. | ||

Ĉefaj trajtoj

1. Bonega Pada Kvalito: Pli malgranda lasero-punkto kaj alta labora efikeco, alta kvalito.

2. Alta Tranĉa Rapido: tranĉa rapido estas 2-3 fojojn ol la sama potenco CO2-lasero-tranĉa maŝino.

3. Stabila Kurado: adoptu pintajn mondajn importajn fibrojn laserojn, stabilan agadon, ŝlosilaj partoj povas atingi 100.000 horojn;

4. Alta Efikeco por fotoelektra konvertiĝo: Komparu kun CO2-lasero-tranĉa maŝino, fibro-lasero-tranĉa maŝino havas tri fojojn fotoelektran konvertan efikecon.

5. Malalta Kosto: Ŝparu energion kaj protektu medion. Fotoelektra konverta rapideco estas ĝis 25-30%. Malmulta elektra konsumo, temas nur pri 20% -30% de tradicia CO2-lasero.

6. Malalta Bontenado: fibro-linio-transdono ne bezonas reflekti lenson, ŝpari bontenan koston;

7. Facilaj Operacioj: transdona linio de fibro, neniu ĝustigo de optika vojo.

Rapidaj Detaloj

Kondiĉo: Nova

Lasero-Tipo: Fibra Lasero

Aplika Materialo: Metalo

Tranĉa Dikeco: Dependas

Tranĉa Areo: 1500x3000mm

Tranĉa Rapido: 500mm/s

CNC aŭ Ne: Jes

Malvarmiga Modo: Malvarmiga Akvo

Kontrola Programaro: BodorPro

Grafika Formato Subtenita: AI, BMP, DXF, PLT

Atestado: CCC, CE, ISO, SGS, UL

Post-venda Servo Provizita: Inĝenieroj haveblaj al serva maŝinaro eksterlande

Ŝlosilvorto: varma vendo metala lasera tranĉmaŝino

Tranĉa dikeco: 0-30mm

Pozicia precizeco: 0.02mm

Tranĉa rapideco: 0-10000mm/min

Tranĉa materialo: Metala neoksidebla ŝtalo karbona ŝtalo aluminio

Apliko: Aluminiaj Litoj

Vise ago Metodo: Duonaŭtomata Krampo Vise

Potenco: Mekanika

Marko: bodor

industrio: juvelarto metalproduktoj aŭtopartoj

Maŝinaj Partoj

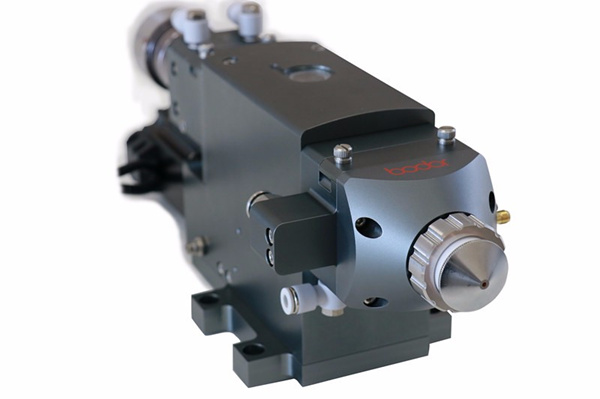

Nomo: BodorGenius Auto Focus Laser Head

1, Aŭtomata fokuso

Aplikebla al diversaj fokusoj, kiuj estas kontrolitaj per maŝina ilo-sistemo. Fokusa punkto aŭtomate ĝustigos en tranĉa procezo por atingi la plej bonan tranĉan efikon de malsamaj dikecaj tukoj.

2, Liberigu Viajn Manojn

La fokusa distanco estas kontrolita de operaciumo. Ni ne bezonas fari manan reguligon, kiu efike evitas erarojn aŭ erarojn kaŭzitajn de mana funkciado.

3, Rapide

(1) Aŭtomata fokuso aŭtomate ĝustigus la plej taŭgajn fokusajn punktojn en la procezo de truado kaj tranĉado, kio multe plibonigas tranĉan rapidon;

(2) Kiam oni anstataŭigas malsamajn materialojn aŭ malsamajn dikajn foliojn, mana fokusa lasera kapo bezonas manan reguligon, kiu estas peniga kaj temporaba; aŭtomata fokusa lasera kapo estas kontrolita de kontrolsistemo, ĝi povas legi sistemajn stokadparametrojn aŭtomate, ŝparante tempon kaj laborforton;

(3)Kolimanta protekta lenso-kesto povas pli bone protekti kolimantan lenson kaj plibonigi anstataŭantan rapidecon de protekta lenso.

4, Precizeco

Pliigante boran fokusan longon, aparte fiksante truan fokusan distancon kaj tranĉantan fokusan distancon, plibonigas tranĉan precizecon.

5, Daŭra

(1) Enkonstruitaj duoblaj akvo-malvarmigaj strukturoj povas certigi la konstantan temperaturon de kolimado kaj fokuso de komponantoj, evitante trovarmigan damaĝon de lensoj, malvarmiga efiko estas pli bona, neniu hejtado aŭ nebuliĝo en longdaŭra tranĉado, serva vivo de lensoj plilongiĝis.

(2) Pliigante koliman protektan lenson kaj fokusan protektan lenson, zorge protektu ŝlosilajn komponantojn.

Nomo: Integrita Casting Machine Body

Uzante flokon grafitan gisferon, kies plej malalta tirforto estas 200MPa. Alta karbonenhavo, alta kunprema forto kaj alta malmoleco. Forta ŝoko-sorbado kaj eluziĝo-rezisto. Malalta termika sentemo kaj lita breĉo-sentemo reduktas la perdon de ekipaĵo dum uzado, do la maŝina precizeco povus konservi dum longa tempo, kaj neniu deformado en vivociklo.

Nomo: Kontrola kabineto

Integrita la laserfonto kaj ĉiuj elektronikaj maŝinpartoj, la kabineto povas protekti la altvalorajn elektrajn partojn kaj multekostajn laserfonton. La ventumilo en la kabineto provizas pli bonan malvarmigan sistemon por la elektraj partoj

Nomo: Aŭtomata lubrika sistemo

Elektra lubrikado estas speco de ilara pumpilo kun racia konstruo, bonega rendimento kaj ampleksaj funkcioj.

Konekte kun programa kontrolsistemo en la ĉefa maŝino, la lubrika sistemo povus kontroli oleo-nivelon ene de tanko same kiel oleotransdona premo kaj fiksi lubrikadon, kio efike malhelpos ruston ene de lubrika sistemo por certigi tranĉan precizecon.