Fibrolasero estas lasero en kiu la aktiva gajnmedio estas optika fibro dopita kun rarateraj elementoj kiel ekzemple erbio.

La maniero kiel ĝi generas sian trabon estas klare diferenca de tiu de Co2-lasero kiu uzas resonatorojn.

Fibraj laseroj estas multe pli ekologiemaj ol Co2-laseroj uzantaj tipe malpli ol 50%-potencan konsumon kompare kun Co2-lasero.

Ili ankaŭ estas pli fidindaj kaj tranĉas partojn ĝis 6mm dikaj 30-40% pli rapide ol Co2 Lasero.

Trajtoj de fibro lasero tranĉanta maŝinon

1.Ekscela trabo-kvalito: Pli malgranda fokusa diametro kaj alta labora efikeco, alta kvalito.

2.Alta tranĉa rapido: tranĉa rapido estas pli ol 20m/min.

3.Stabila kurado: adoptante la pintajn mondajn importajn fibrojn laseroj, stabila agado, ŝlosilaj partoj povas atingi 100.000 horojn

4.Alta efikeco por fotoelektra konvertiĝo: Komparu kun CO2 lasera tranĉmaŝino, fibra lasera tranĉmaŝino

havas trifoje fotoelektran konvertan efikecon

5. Malpli kosto: Ŝparu energion kaj protektu ĉirkaŭrigardon. Malpli elektran konsumon.

6.Low-bontenado: fibra linio-transdono, neniu bezono reflekti lenson, ŝpari daŭrigan koston;

7. Facilaj operacioj: transdono de fibro-linio, neniu ĝustigo de optika vojo;

Teknika Dato de fibro lasero tranĉanta maŝinon

| Modelo | fibro lasero tranĉanta maŝinon | ||

| Lasera tipo | Raycus fibra lasero | ||

| Lazera labormedio | Fibro | ||

| Lasera ondolongo | 1064 nm | ||

| Lasera potenco | 300w, 500w, 750w, 1000w ktp | ||

| Trabo-kvalito | <0,373mrad | ||

| Kontrola sistemo 4 aksoj | Bochu (Farita en Ŝanhajo) | ||

| Sistemlingvo | Multlingvoj | ||

| Tranĉanta kapo | US26 | ||

| Motoro | 750W YASKAWA servo (Fabrita en Japanio) | ||

| Rapida reduktilo | Delta | ||

| Transdono kaj gvidreloj | Transdona vojo por X Y-akso | Raka ilaro (Farita en Germanio) | |

| Gvidreloj por XY-akso | Importita HIWIN Kvadrata gvidrelo | ||

| Pilkŝraŭbo por Z-akso | THK pilkŝraŭbo (el Japanio) | ||

| Tabelo | Segildento | ||

| Akvomalvarmilo | 1P | ||

| Rotacia sistemo | Diametro de rotoro | 100mm (povas fakte ĝis 150mm) | |

| Longo de rotoro | laŭ via peto | ||

| Industria komputilo | Yan hua | ||

| Efika tranĉa gamo | 3000* 1500mm | ||

| Grafika formato subtenata | Aŭtomata kad, Corel draw, PLT, DXF, BMP, AI, DST, DWG, ktp | ||

| Tablo aksa poziciiga precizeco | ≤ ± 0,03mm / m | ||

| Ripetu tabelon pri poziciiga precizeco | ≤±0.02mm/m | ||

| Tranĉanta rapideco | ≤30m/min | ||

| Maksimuma tranĉa dikeco | 10 mm (laŭ lasera potenco) | ||

| Maksimuma tabloŝarĝo | 1600KG | ||

| Potencaj Taksoj | Trifaza 380V 60Hz | ||

| Potenco | 6-20KW | ||

| Tuta potenco-protekta klaso | IP54 | ||

1 Raycus-fibra lasero-generatoro

2 US 26 tranĉkapo

3 Bochu kontrola sistemo

4 Japanio Omron limŝaltilo

5 Akvo-frigilo 1p

5 Germana rapidoreduktilo

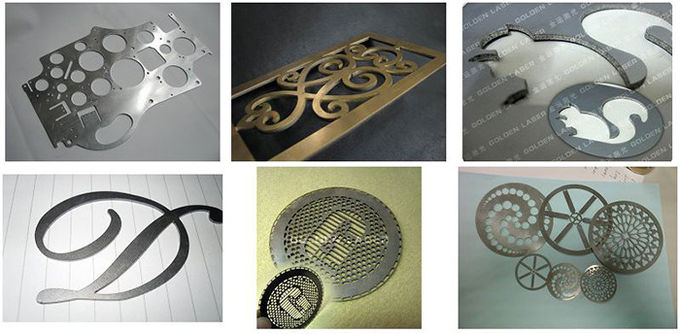

Aplikoj materialoj de fibro lasera tranĉmaŝino

Fibraj Laseraj Tranĉaj Maŝinoj estas vaste uzataj en fabrikado de Afiŝtabulo, Reklamado, Signoj, Signagejo, Metalaj Literoj, LED-Leteroj, Kuirejaj Varoj, Reklamaj Leteroj, Lado-Pretigo, Metalaj Komponantoj kaj Partoj, Feraĵo, Ĉasio, Rakoj kaj Kabinetoj, Metalaj metioj, metalaj artaĵoj, lifta panelo tranĉado, aparataro, aŭtopartoj, Okulkadro, Elektronikaj Partoj, Nomplatoj, ktp.

Taŭgas por neoksidebla ŝtalo, milda ŝtalo, karbona ŝtalo, aloja ŝtalo, printempa ŝtalo, fero, galvanizita fero, galvanizita lado, aluminio,

kupro, latuno, bronzo, oro, arĝento, titanaj platoj, metalaj folioj, metalaj platoj, metalaj tuboj kaj tuboj, ktp.

Aplika Industrio:

Fibraj Laseraj Tranĉaj Maŝinoj estas vaste uzataj en fabrikado de Afiŝtabulo, Reklamado, Signoj,

Signaloj, Metalaj Literoj, LED-Leteroj, Kuirejaj Vazaĵoj, Reklamaj Leteroj, Lado-PretigoMetalaj Komponantoj kaj Partoj, Feraĵo, Ĉasio, Rakoj & Kabinetoj-Pretigo,

Metalmetioj, metalaj artaĵoj, lifta paneltranĉado, aparataro, aŭtopartoj, Okulfrapo, Elektronikaj Partoj, Nomplatoj, ktp.

Malmultekosta 500W CNC Metala Fibro Laser Tranĉa Maŝino por Vendo

Tranĉa kapablo & Konsumo

| Materialo | Dikeco (mm) | Rapido (mm/s) | Gasa Premo (MPa) | Gaso | Tranĉa Alteco |

| Senrusta ŝtalo | 0.5 | > 200 | 1 | N2 | 0.6 |

| 1 | 90~120 | > 1.1 | N2 | 0.6 | |

| 2 | 16~20 | > 1.5 | N2 | 0.6 | |

| Karbona Ŝtalo | 1 | 120~150 | 1 | O2 | 1 |

| 2 | 35~45 | 0.6~0.8 | O2 | 1 | |

| 3 | 15~18 | 0.3~0.5 | O2 | 1 |

Niaj Servoj

1)24 Monatoj por por la tuta maŝino.

2) Ĉiuj maŝinoj estos plene provitaj antaŭ sendo.

3)Laser-tubo 100000 horoj da labortempo.

4) 24 horoj teknika subteno - retpoŝto, telefono aŭ video interrete.

5) Amika angla manlibro por uzado kaj prizorgado de maŝinoj.