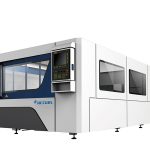

Priskribo de la produkto

1.Metala Lasera Tranĉa Maŝino Trajtoj

Adoptante altnivelan fibran laseran generatoron kaj pilkan ŝraŭban movan sistemon, ĝi povas tranĉi kaj trui malsamajn metalajn materialojn kun alta precizeco kaj alta rapido.

Ĉar lasero estas transdonita per fibro, ne necesas prizorgi aŭ ĝustigi la laseran optikan vojon. Ĝi multe reduktas la imposton de misfunkciadoj de maŝinoj kaj plilongigas la laborvivon. Grandformata tranĉa areo renkontas la postulojn de diversaj specoj de metala pretigo.

2.Metala Lasera Tranĉa Maŝino aplikataj materialoj

Ĉefe uzata por tranĉi karbonŝtalon, silician ŝtalon, neoksideblan ŝtalon, aluminian alojon, titanan alojon, galvanizitan ŝtalon, peklan tabulo, aluminian zinkan platon, kupron kaj multajn specojn de metalaj materialoj tranĉantaj ktp.

3.Metala Lasera Tranĉa Maŝino aplikataj industrioj

Fibra lasera tranĉmaŝino aplikata en ladpretigo, aviado, kosmoflugo, elektroniko, elektraj aparatoj, metropartoj, aŭtomobilo, maŝinaro, precizecaj komponantoj, ŝipoj, metalurgia ekipaĵo, lifto, hejmaj aparatoj, donacoj kaj metioj, ilpretigo, ornamado, reklamado, metalo fremda prilaborado diversaj fabrikado prilaborado industrioj.

4.Avantaĝoj de Lasera Tranĉa Maŝino:

1) Bonega trabo kvalito: Pli malgranda fokusa diametro kaj alta labora efikeco, alta kvalito.

2) Alta tranĉa rapido: Tranĉa rapideco estas pli ol 20m/min

3) Stabila kurado: Adoptante la plej bonajn mondajn importajn fibro-laserojn, stabila agado, ŝlosilaj partoj povas atingi 100,000 horojn;

4) Alta efikeco por fotoelektra konvertado: Komparu kun CO2-lasero-tranĉa maŝino, fibro lasera tranĉa maŝino havas tri fojojn fotoelektran konvertan efikecon

5) Malalta kosto & Malalta bontenado: Ŝparu energion kaj protektu medion. Fotoelektra konverta indico estas ĝis 25-30%. Malalta elektra konsumo, ĝi estas nur ĉirkaŭ 20% -30% de tradicia CO2 lasera tranĉmaŝino. Fibra linio transdono ne bezonas reflekti lenson, ŝparu bontenado kosto;

6) Facilaj operacioj: transdono de fibro-linio, neniu ĝustigo de optika vojo;

7) Super flekseblaj optikaj efikoj: Kompakta dezajno, facila al fleksebla fabrikado postuloj.

Teknikaj Datumoj de Lasera Tranĉmaŝino

| Lasera Potenco | 500W |

| Lasera Fonto | Mondfama Germanio IPG aŭ Usono N-luma Fibra laserfonto |

| Lasero-Tipo | Importita Fibra Lasero |

| Lazera Teknologio | Germanio Teknologio |

| XYZ Laborareo | 1500*3000 mm*150mm |

| Maks. Tranĉa Dikeco (Karbona Ŝtalo) | 1 mm |

| Maksimume Tranĉanta Rapido | 5-14 Metroj / Min (ĝis materialoj) |

| Lasera ondolongo | 1070nm |

| Minimuma linilarĝo | ≤0.1mm |

| Precizeco pri loko | ≤ ± 0,05mm |

| Re-loka precizeco | ± 0,02mm |

| Maks. movanta rapideco | 100m / min |

| Subtenanta Formato | PLT, DXF, BMP, AI |

| Potenco postulo | 220V/50Hz/1Ph |

| Malvarmiga Vojo | Akvotrinkado |

| Komputila maks. ŝarĝi | 1000KGS |

| Transdona Metodo | Pilka Ŝraŭba Transdono |

| Tablo-movita sistemo | Japana Importita Panasonic Servo-Motoro kaj Veturado-Sistemo |

| Fokusa Metodo | Sekvas kaj Aŭtomata Alĝustiga Fokuso |

| Kontrola Metodo | Senkonekta Movada Kontrolo |

| Kontrolo programaro | Perfekta Lazera Profesia Lazera Tranĉa Programaro |

Rapidaj Detaloj

Apliko: Laser-Tranĉado

Kondiĉo: Nova

Lasero-Tipo: Fibra Lasero

Aplika Materialo: Metalo

Tranĉa Dikeco: 1-5mm, 0-20mm

Tranĉa Areo: 1500*3000mm/1300*2500mm/600*400mm

Tranĉa Rapido: 0-60 m/minuto

CNC aŭ Ne: Jes

Malvarmiga Modo: Malvarmiga Akvo

Kontrola Programaro: Perfekta Laser Profesia tranĉa programaro

Grafika Formato Subtenita: AI, BMP, DST, DXF, DXP, PLT

Loko de Origino: Anhui, Ĉinio (Mainland)

Brandnomo: ACCURL

Atesto: CE, ISO

Post-venda Servo Provizita: Inĝenieroj haveblaj al serva maŝinaro eksterlande

Maks. movanta rapido: 40m/min por Metala Lasera Tranĉa Maŝino

Labortablo Max. Ŝarĝo: 2000kgs por Metala Lasera Tranĉa Maŝino

Transdona Metodo: Pilka Ŝraŭbo Transdono por Metala Lasera Tranĉa Maŝino

Loka Precizeco: ≤±0.05 mm por Metala Lasera Tranĉa Maŝino

Lasera Potenco: 500w / 1kw

Potenco Postulo: 380V/50HZ/3PH, 220V/50HZ/1Ph

Driving Way: importita Servomotoro

Min line line: 0.1nm

Dum kaj transdona maniero: Importita servomotoro kaj lineara